Digital technology revolutionizes paint finish quality standards in automotive repair, leveraging high-res cameras, spectrophotometers, and software for precise analysis. This enhances consistency, accuracy, and customer satisfaction, with real-time feedback enabling immediate adjustments to maintain exceptional standards, crucial for premium brands like Mercedes-Benz.

Digital technology is revolutionizing the way we monitor paint finish quality standards. From digital tools for accurate paint analysis to streamlined quality control processes, real-time data collection, and consistent finishing, modern innovations are transforming the automotive and industrial sectors. By leveraging advanced sensors, AI algorithms, and cloud-based platforms, manufacturers can achieve unparalleled precision, reduce errors, and ensure consistently high-quality finishes. This evolution in digital monitoring is a game-changer for maintaining rigorous paint finish quality standards.

- Digital Tools for Accurate Paint Analysis

- Streamlined Quality Control Processes

- Real-Time Data for Consistent Finishing

Digital Tools for Accurate Paint Analysis

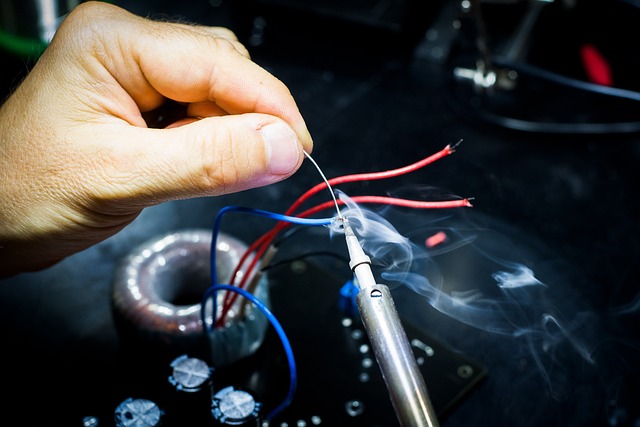

In today’s digital era, the automotive industry has seen a remarkable revolution in paint finish quality standards monitoring. Advanced digital tools are transforming how manufacturers and auto repair services ensure perfection in vehicle collision repair and car dent removal processes. One of the most significant advantages is the ability to conduct precise paint analysis using high-resolution cameras and spectrophotometers. These instruments capture detailed data on color, texture, and surface defects, allowing for accurate comparisons with industry standards.

Through specialized software, these digital tools provide real-time feedback, enabling technicians to make immediate adjustments during the painting process. This enhances consistency and accuracy, ensuring that every vehicle leaves the workshop with a flawless finish. By implementing these innovative practices, auto repair services can maintain and even elevate paint finish quality standards, catering to customers seeking top-tier repairs for their vehicles, whether it’s a simple dent removal or comprehensive collision repair.

Streamlined Quality Control Processes

Digital technology has revolutionized paint finish quality standards monitoring, bringing about significant improvements in efficiency and precision. Automated systems and advanced software now play a pivotal role in streamlining quality control processes within vehicle repair and auto maintenance facilities, including auto collision centers. These innovations enable thorough inspections, identifying even the subtlest defects that might have gone unnoticed with traditional methods.

By leveraging digital tools, technicians can quickly capture high-resolution images of painted surfaces, analyze color consistency, detect surface irregularities, and record detailed data for each vehicle. This real-time information sharing enhances collaboration among teams, ensuring everyone is aligned with the latest quality standards. As a result, auto collision centers can maintain consistent paint finish excellence, fostering customer satisfaction and building a reputation for superior auto maintenance services.

Real-Time Data for Consistent Finishing

In the realm of automotive craftsmanship, achieving consistent paint finish quality standards is paramount, especially for brands like Mercedes-Benz known for their meticulous attention to detail in vehicle restoration and collision repair. Digital technology plays a pivotal role here by enabling real-time data collection during the finishing process. This ensures that every stroke, spray, and touch-up is accurately monitored, allowing for immediate adjustments if deviations from the desired standard occur.

Through integrated sensors and high-resolution cameras, digital systems can detect even subtle inconsistencies, such as irregular paint thickness or minor scratches, in real time. This data not only helps in maintaining precision but also facilitates predictive maintenance by identifying when equipment or techniques need calibration or replacement. Thus, it streamlines the process of scratch repair and ensures that every finished product meets the highest quality benchmarks, be it a meticulous Mercedes-Benz collision repair or any other vehicle restoration task.

Digital technology has revolutionized paint finish quality standards monitoring, offering accurate analysis through advanced tools, streamlining quality control processes, and providing real-time data for consistent finishing. By embracing these innovations, industries can maintain higher standards, reduce errors, and ensure customer satisfaction in every coat of paint applied.