The automotive industry demands high paint finish quality standards in car repair services, focusing on aesthetics and structural integrity. High-volume body shops face challenges maintaining consistency due to workload pressures and technician skill variations. Regular training, standardized procedures, tool calibration, and digital technologies are employed to ensure superior paint finish quality standards for every customer visit.

In today’s fast-paced automotive industry, high-volume repair shops must maintain stringent paint finish quality standards. This article delves into the intricate process these shops employ to ensure consistent, high-quality finishes despite the challenges of rapid turnover and heavy workloads. From understanding evolving industry norms to implementing robust quality control measures, we explore strategies that empower repairs to meet—and exceed—paint finish expectations.

- Understanding Paint Finish Quality Standards

- Challenges in High-Volume Repair Environments

- Strategies for Consistent Quality Control

Understanding Paint Finish Quality Standards

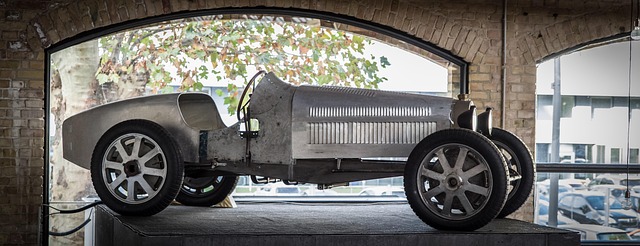

Paint finish quality standards are non-negotiable in the automotive industry, especially in high-volume car repair services and car body shops. These standards ensure that every vehicle leaving the shop not only looks pristine but also maintains a durable, protective coat. The primary goal is to achieve a smooth, even surface free from defects like bumps, runs, or orange peel texture. This involves meticulous preparation of the car’s surface before application, strict adherence to recommended drying times, and precise spraying techniques to avoid overspray and ensure consistent paint thickness.

Car dent repair processes must adhere to these standards to restore not just the visual appeal but also the structural integrity of the vehicle. High-quality paint finishes in car body shops require a deep understanding of various factors, including surface preparation, paint composition, environmental conditions, and application methods. Maintaining these standards is crucial for customer satisfaction and ensuring the longevity of the vehicle’s appearance.

Challenges in High-Volume Repair Environments

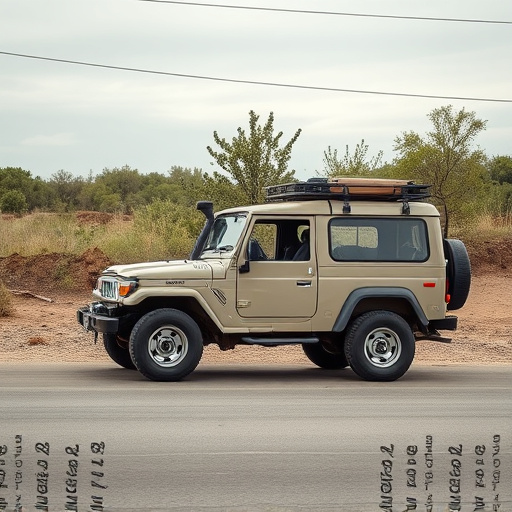

In high-volume repair environments, shops face unique challenges when it comes to maintaining paint finish quality standards. The constant flow of vehicles requires efficient workflows and consistent application techniques to ensure each car receives the same level of meticulous attention. Time constraints often lead to a race against the clock, where quick turnaround times can compromise the precision and detail required for premium finishes, particularly in luxury vehicle repair and vehicle restoration projects.

Additionally, managing consistency across multiple technicians is another hurdle. Different skill levels and interpretations of standards can result in variations in paint application, especially during car scratch repair processes. This inconsistency may manifest as uneven color blends, imprecise edge work, or visible brush strokes, compromising the overall aesthetic appeal. Therefore, regular training sessions and standardized procedures are essential to overcome these challenges and uphold high-quality paint finish standards in busy repair facilities.

Strategies for Consistent Quality Control

To maintain consistent paint finish quality standards during high-volume repairs, vehicle body shops implement robust quality control strategies. These often involve specialized training for technicians to ensure they’re adept at handling various paint types and finishes accurately. Standardized procedures, like using identical equipment and materials across all repair projects, play a crucial role in preserving uniformity. Regular calibration of tools and consistent application techniques help maintain precision, resulting in flawless paints that match the original vehicle’s finish perfectly.

Additionally, many shops adopt digital technologies for detailed paint analysis and comparison. This includes utilizing specialized lighting to detect even subtle variations in sheen and texture, as well as employing computer-aided design (CAD) software to compare repaired areas with the vehicle’s original specifications. Integrating such advanced tools enables shops to catch issues early, making necessary adjustments on the spot or tweaking future repair approaches to ensure consistently superior paintless dent repair and collision repair outcomes for every customer’s vehicle body shop visit.

Shops facing high-volume repair challenges can maintain consistent paint finish quality standards through strategic quality control measures. By understanding the specific demands of these environments and implementing tailored strategies, businesses can ensure a professional, durable, and visually appealing finish on every repair project. This commitment to quality not only boosts customer satisfaction but also builds trust in the shop’s capabilities, fostering long-term relationships with clients who demand excellence.