Paint thickness, measured by dry film thickness (DFT), is critical for paint finish quality standards in automotive repairs like Mercedes Benz collision repair. Accurate measurement tools prevent imperfections, ensuring optimal application, customer satisfaction, and component lifespan. Optimal paint thickness achieves aesthetic excellence and structural integrity, hiding imperfections and safeguarding substrates from too much or too little paint. Consistent paint finish quality standards are vital for visual appeal, durability, and seamless integration in all applications, from art to industrial sectors.

In the pursuit of exceptional paint finishes, understanding paint finish quality standards begins with one crucial factor: thickness. The depth and consistency of paint application significantly impact both aesthetics and longevity. This article delves into the metrics defining paint thickness, explores its effects on visual appeal and structural integrity, and emphasizes the importance of maintaining uniform standards for consistently superior results. From vibrant hues to durable protection, optimal paint thickness is the unsung hero behind every stunning, long-lasting finish.

- Understanding Paint Thickness Metrics

- Impact on Aesthetic Appeal and Durability

- Ensuring Consistent Quality Standards

Understanding Paint Thickness Metrics

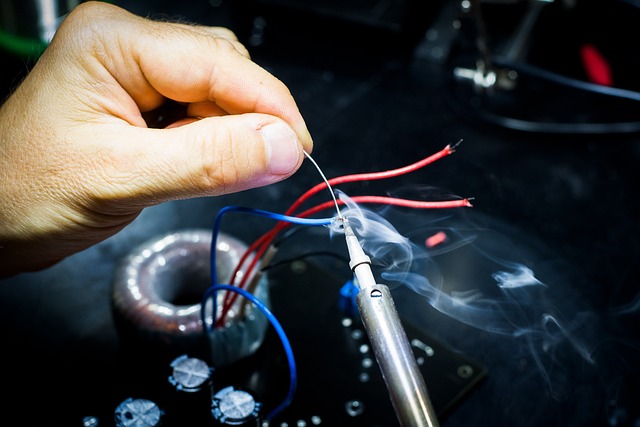

Paint thickness plays a pivotal role in achieving and maintaining paint finish quality standards. Understanding metrics like dry film thickness (DFT) is essential for ensuring consistent, high-quality results across various automotive applications, such as collision repair, dent repair, and bumper repair. DFT measures the amount of paint applied to a surface, providing a clear indication of coverage and potential issues like over- or under-application.

Accurate measurement tools help professionals in these fields achieve optimal paint finish quality standards. By controlling paint thickness, technicians can prevent visible imperfections like orange peel, uneven shading, or delaminations that compromise the aesthetics and durability of the repair. This, in turn, enhances customer satisfaction and ensures the longevity of repaired components, whether it’s a damaged fender, a dented door panel, or a faded bumper.

Impact on Aesthetic Appeal and Durability

The thickness of paint plays a pivotal role in determining both the aesthetic appeal and durability of a finished surface. A paint job that meets the desired paint finish quality standards should not only look smooth and even but also provide adequate protection to the underlying substrate. Insufficient paint thickness can result in visible imperfections, such as brush strokes or uneven application, which compromise the overall visual attractiveness. Conversely, excessive paint build-up may create a rough texture or lead to yellowing over time, negatively impacting the initial aesthetic appeal.

In the context of mercedes benz collision repair and auto body repair, maintaining optimal paint thickness is crucial for restoring vehicles to their pre-accident condition. Vehicle collision repair often involves complex processes where precise paint application techniques are employed to match the original factory finish. Skipping proper preparation or using low-quality paints can affect not just the appearance but also the longevity of the repair. Just as a well-crafted vehicle collision repair should seamlessly integrate with the existing body panels, achieving the right paint thickness ensures that the finished product is not only visually pleasing but also durable enough to withstand the rigors of daily use.

Ensuring Consistent Quality Standards

Maintaining consistent quality standards is paramount in any painting process, be it for artistic purposes or industrial applications like vehicle repair services and auto repair shops. When it comes to paint finish quality standards, one of the key factors is ensuring that the paint is applied at the correct thickness. This is crucial as it directly impacts the aesthetics, durability, and longevity of the finished product. In vehicle collision repair, for instance, achieving the right paint thickness guarantees a seamless blend with existing surfaces, eliminating unsightly inconsistencies or patchy finishes.

Consistent quality means that every painted surface adheres to predetermined specifications, ensuring that each layer of paint is evenly applied and sufficiently thick. This precision prevents issues such as visible brush strokes, uneven drying times, and potential delaminations over time. By upholding these standards, whether for residential, commercial, or automotive applications (like those provided by vehicle repair services), the final product not only meets but exceeds expectations, contributing to a high-quality, lasting result.

Maintaining optimal paint thickness is paramount for achieving superior paint finish quality standards. By understanding key metrics, evaluating aesthetic appeal and durability impacts, and implementing consistent quality control measures, professionals can ensure robust and visually appealing finishes that stand the test of time. This meticulous approach to paint application is essential for delivering high-satisfaction results in any project.